LPKF CuttingMaster 2000 – The Most Cost-Effective Laser Depaneling System

LPKF CuttingMaster Series 2000 is a very compact machine with minimal footprint. Equipped with CleanCut Technology, guarantees technically clean cutting edges.

LPKF CuttingMaster 2000 series is a reasonable priced, high-throughput workhorse. LPKF CuttingMaster levels-out the former cost advantage that mechanical routers used to have. Using these LPKF Systems for depaneling tasks, results in superior quality at a comparable investment to mechanical methods.

- Optimized price-performance ratio

- CleanCut Technology

- Compact system

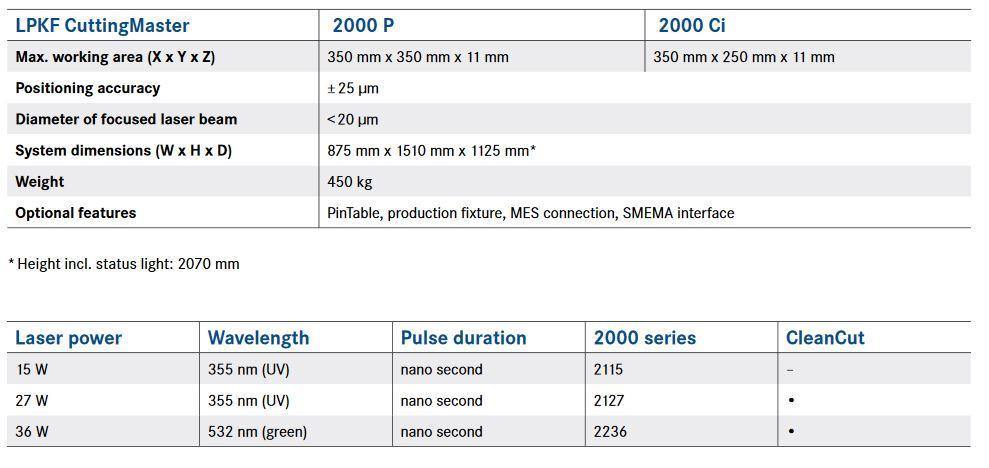

- UV & Green laser available - up to 36W

- Standalone & integrable version available

Download LPKF CuttingMaster 2000 Series Brochure

Features and Benefits

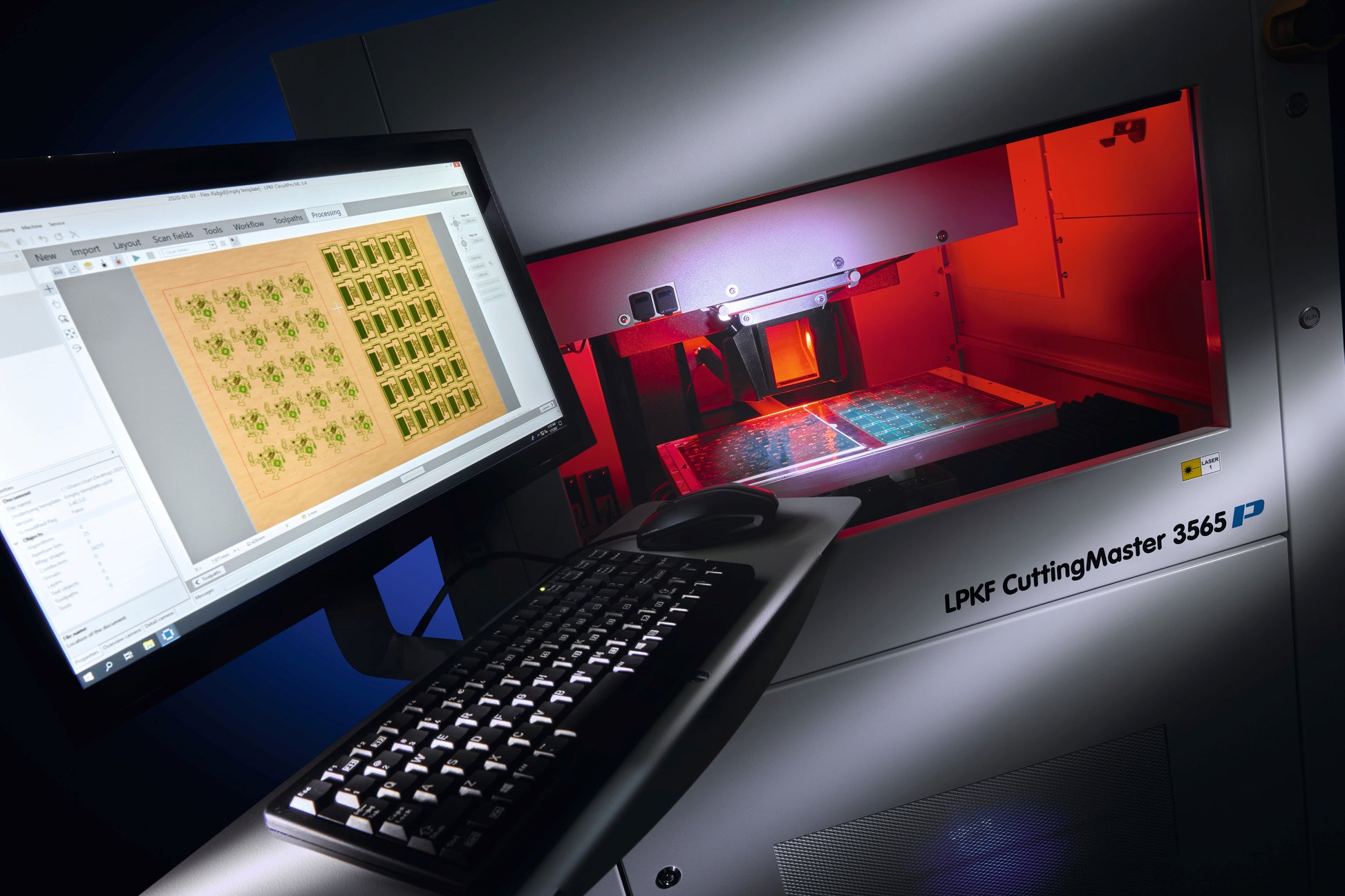

Accurate: Specially developed high-quality hardware include with technically perfected software ensures precision and high production.

Cost-efficient: LPKF CuttingMaster ensure highest CleanCut quality laser cutting with price of conventional depaneling processes.

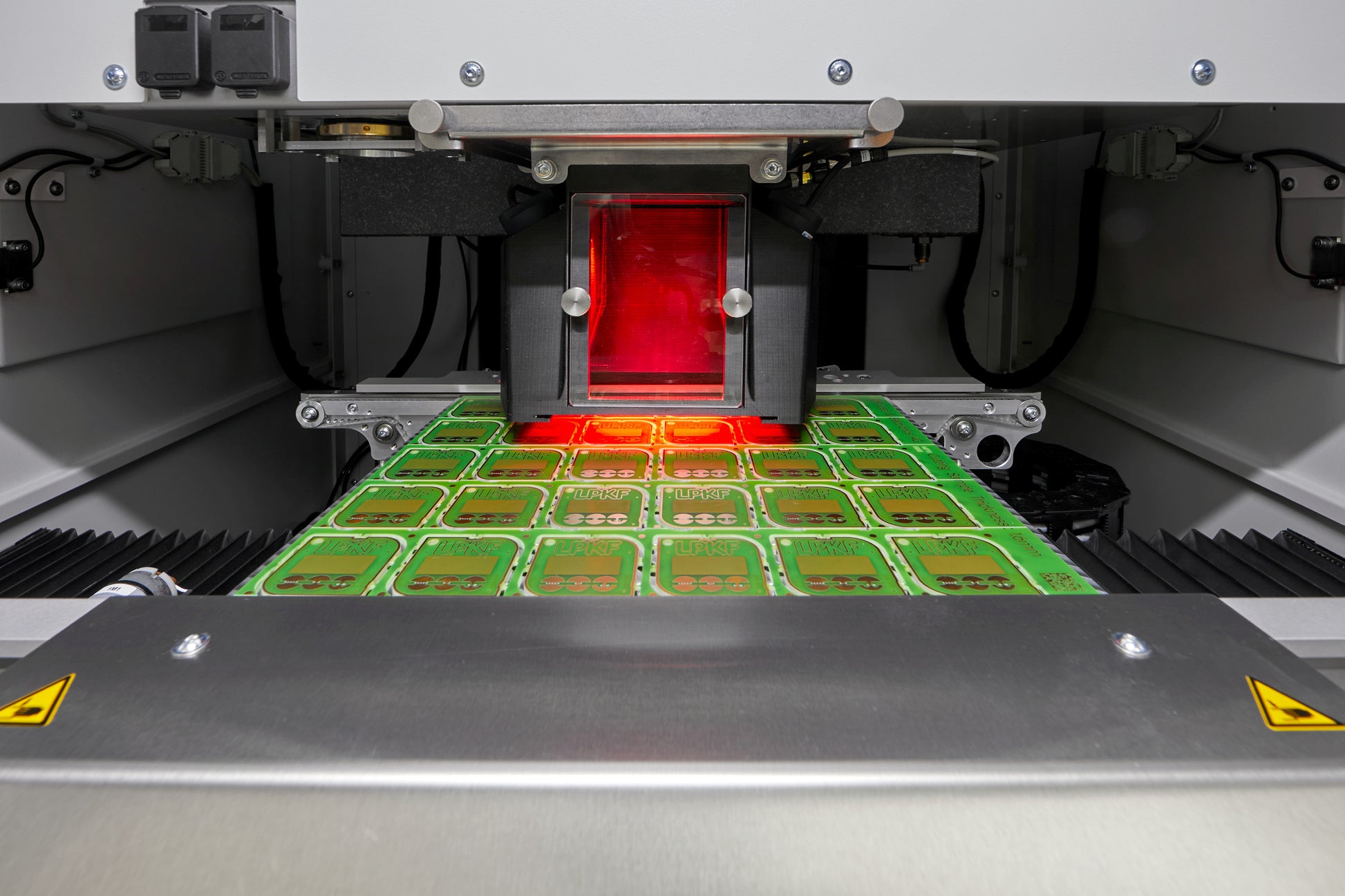

Clean: Clean cutting edges with application specific configuration of laser process. Contamination free via effective exhaust unit.

Reliable: LPKF CuttingMaster technology manages 24/7 production in highly demanding industrial sectors: automotive, medical technology and consumer electronics.

Versatile: Ability to process rigid to flexible materials. Adjustable handling versions with fixture or vacuum table solutions available - as standalone or inline solution.

Fast: Speed processing with continuous process optimization and machine performance.

Automated: Adjustable grade of automation of manufacturing process.

Material Saving: No stress, no contact material processing and cutting channels with only few μm enable a more efficient use of materials.

Optimum Service: Worldwide premium customer support available