LPKF CuttingMaster 3000 – Most Precise Laser Depaneling System

The CuttingMaster 3000 systems are designed to achieve the highest quality results for almost any cutting task. LPKF's proprietary CleanCut technology enables even the most demanding applications where absolute technical cleanliness of the cut edges is essential.

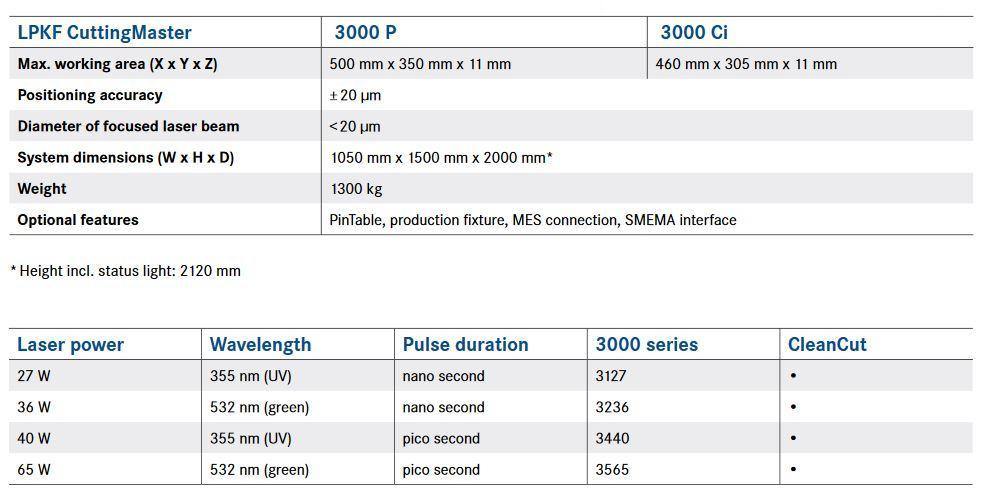

LPKF CuttingMaster 3000 series systems are equipped with linear drives. This ensures very high positioning accuracy and thus better performance. The working range is larger compared to LPKF 2000 series.

The ability to integrate a wide range of different laser sources with different wavelengths and pulse durations in the nano and picosecond range allows systems for very different applications and materials to be used.

LPKF CuttingMaster 3000 can also be used for drilling applications. The sturdy granite table of this series guarantees dependable precision.

- Larger working area

- Highest accuracy

- CleanCut Technology

- Flexible system

- UV & Green laser available - up to 65W

- Standalone & integrable version available

- Patented Tensor Technology

Download LPKF CuttingMaster 3000 Series Brochure

Features and Benefits

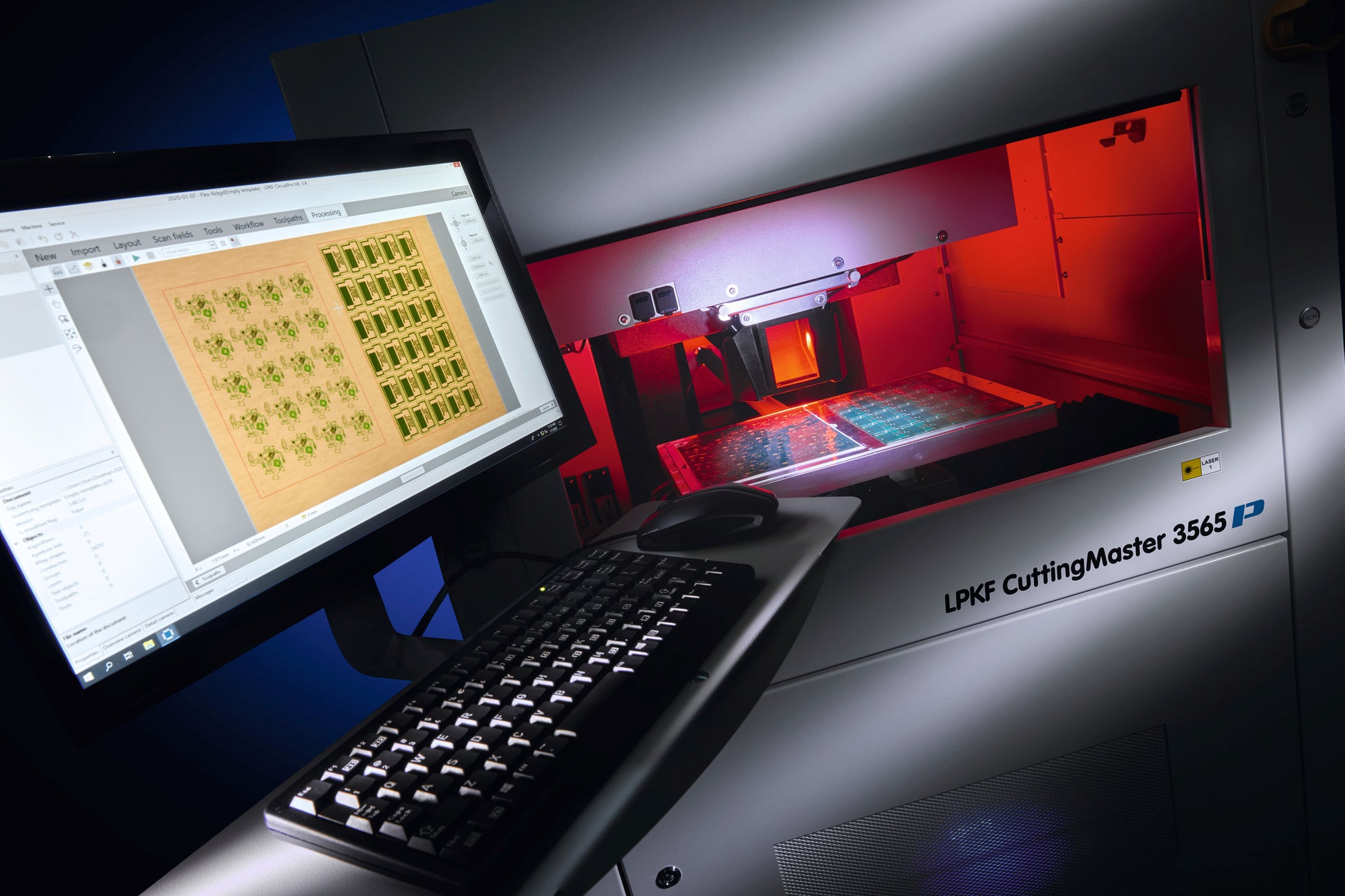

Accurate: The synergy of high-quality hardware and specially developed, technically perfected software ensures precision and high production throughput.

Cost-efficient: By using LPKF CuttingMaster, you will get highest CleanCut quality laser cutting in the price range of conventional depaneling processes.

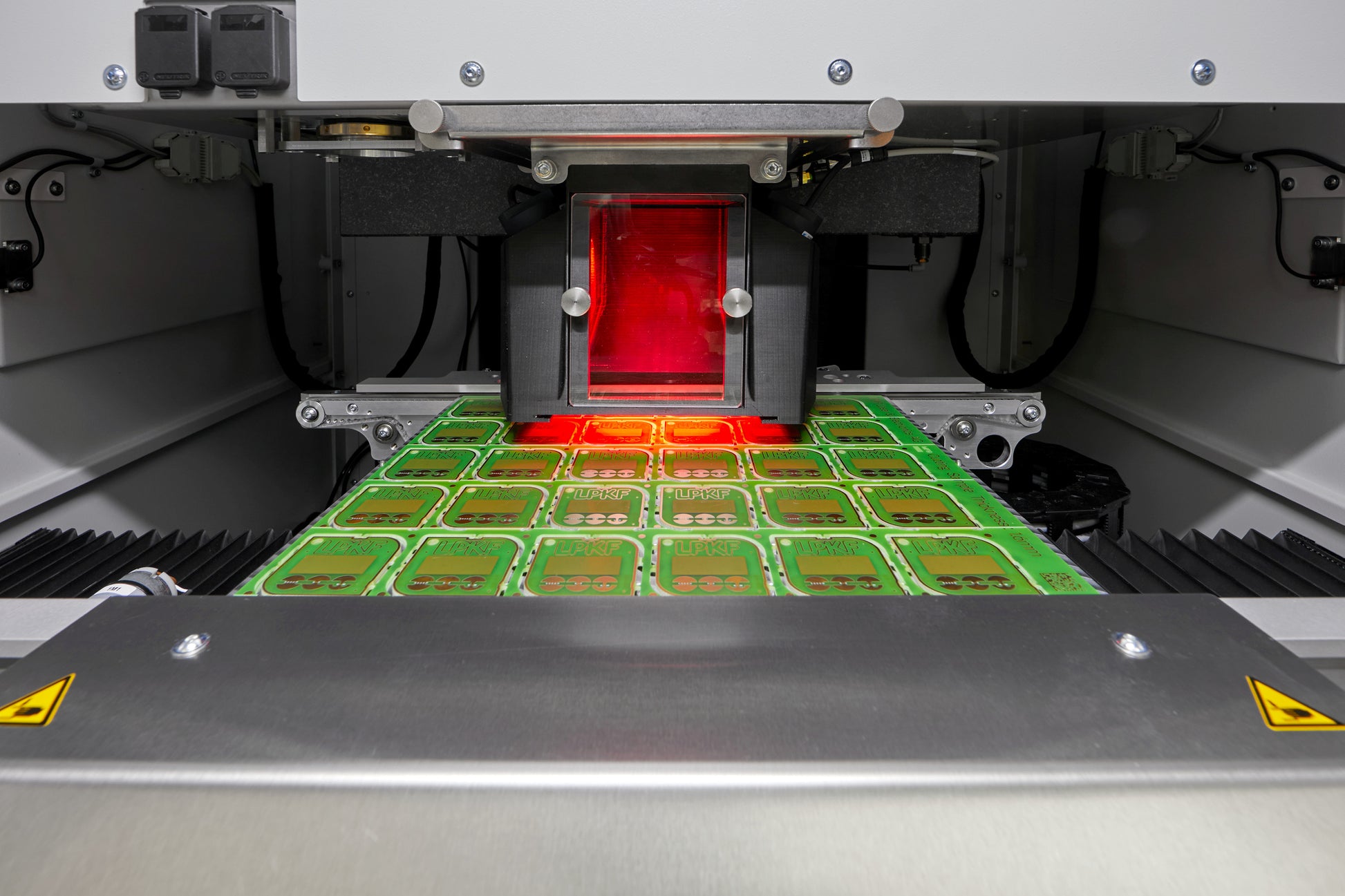

Clean: Throughout the entire process: Application-specific configuration of the laser process guarantees clean cutting edges; and the effective exhaust unit ensures that the surfaces will stay contamination free.

Reliable: The LPKF technologies in the CuttingMaster Systems are proven for highly-demanding industrial sectors like automotive, medical technology, and consumer electronics, and they are suitable for 24/7 production.

Versatile: Materials ranging from rigid to flexible may be processed; different handling versions with fixture or vacuum table solutions are available – whether as a standalone or inline solution.

Fast: Continuous process optimization and a high level of machine performance ensure fast processing.

Automated: The grade of automation of the manufacturing process may be chosen by request.

Material Saving: Stress-free, non-contact material processing and cutting channels with only few μm enable a more efficient use of materials.

Optimum Service: Worldwide premium customer support.

A special award for a particularly powerful depaneling system

The high performance and cost-effectiveness of the LPKF CuttingMaster 3565 as well as the technical cleanliness of the PCB edges as a result of the optimized laser cutting process were the decisive criteria for the Global SMT & Packaging expert jury and winning the Global Technology Award in the Depaneling System category.