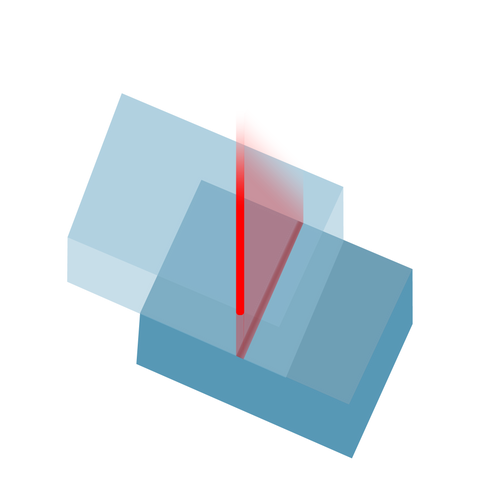

Types of Laser Plastic Welding: Quasi-Simultaneous Welding

In quasi-simultaneous welding, the laser beam is guided along the weld seam and can be steered in the X and Y directions. The laser continues to deliver energy until the desired welding depth has been reliably attained. Due to the high scanning speed, the material melts along the entire weld seam, causing the components to join more or less at the same time. Seam monitoring allows qualitative statements to be made about the welding result. Pyrometer monitoring reliably detects flaws in the weld seam.

Main applications:

Sealing large quantities of sensor or electronic housings

Main characteristics:

- Clean and reliable 2D component joints

- Particularly cost-effective (short cycle times and large batch numbers)

- Process monitoring

- Very flexible due to the ability to program the scanning units

- Corrections of the welding contour or new products without the need for other optics or masks

- Ideal for components up to at most 400 mm x 400 mm in size

- Significantly reduced tooling costs compared to non-laser-based processes