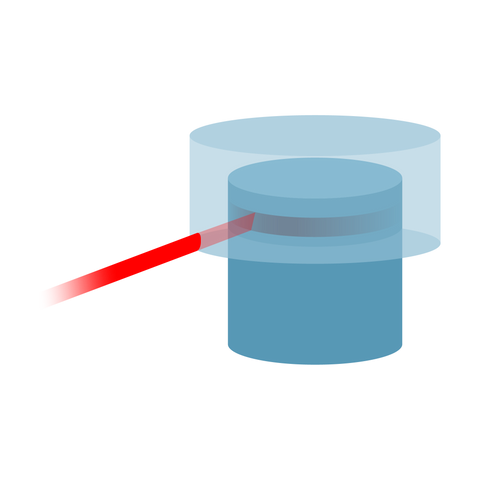

Types of Laser Plastic Welding: Radial Welding

A radial welded application is typically cylindrical in shape and the laser beam makes multiple passes along the entire circumference of the part. The most common approach of radial welding is for the laser beam to be in a fixed position while the part to be welded is spun on an axis.

If the component itself cannot be rotated, then alternative versions of this welding procedure are used: Either the optics spin around the stationary component, or a mirror and scanner-based laser head focus the laser beam on a revolving, horizontal welding plane.

Main applications:

Joining cylindrical bodies, e.g. valves

Main characteristics:

- Simpler and more robust system structure

- Faster welding process through rotating movement

- Reliable process monitoring

- Possibility of adjusting parameters

- Dependable quality with an unbeatable good parts yield rate