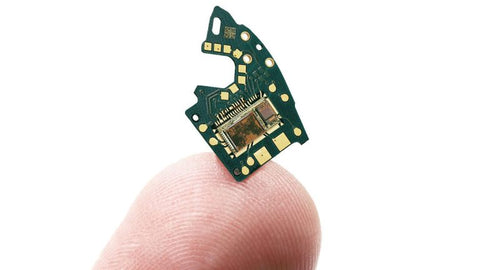

Depaneling of PCBs for a Wide Variety of Materials

Types of Depaneling

Depending on the requirements, depaneling can be performed by either mechanical milling or laser depaneling. The LPKF Protomat and Protolaser machines can be used for depaneling, separating the printed circuit board from the base material.

An extensive parameter/tool library delivers the settings for the most important materials. The creation of panels is also optimally supported by the LPKF software.

| Mechanical Depaneling | Standard printed circuit board materials like FR4 and FR5 are effectively depaneled using LPFK Protomats' special milling tools. The combination of a vacuum table and optical fiducial detection turns inserting and aligning of a panel into a quick and easy task. The breakout tabs are cut cleanly, providing the user with a PCB with an exact contour. |

| Laser Depaneling | The LPKF Protolaser cuts any contour in thin rigid, rigid-flex, or flexible PCB materials. The thermal energy of the laser is used to remove the material path by path/layer by layer. The material is vaporized and the powerful suction system will extract the resulting fumes, resulting in minimal or no residues. |

PCB Contour Routing with ProtoMat S103

LPKF ProtoLasers (Laser Depaneling)

|

ProtoLaser S4 Structure, engrave and cut in a single operation |

|

ProtoLaser R4 Laser ablation with practically no heat transfer |

|

ProtoLaser U4 Compact laser system producing fine, precise structures |

|

ProtoLaser ST High performance, table top compact laser for any lab |

LPKF ProtoMat (Mechanical Depaneling)

|

ProtoMat E44 For cost effective, professional in-house prototyping |

|

ProtoMat S64 All-rounder for rapid PCB prototyping |

|

ProtoMat S104 Specialist for RF and microwave applications |